Your Partner in Natural Products Research

At Herbanext, we are dedicated to supporting the endeavors of students and researchers engaged in studying the fascinating realm of natural products. Our laboratories are equipped with cutting-edge technology and staffed by experienced professionals, all committed to advancing the field of natural product research.

Analytical Services

Run by a diverse and competent team of chemists, chemical technicians, food technologists, and microbiologists, our Analytical & Laboratory Services (ALAB) unit is our powerhouse for laboratory testing and quality control analyses.

We work through a fee-for-service model to extend our testing services to support the endeavors of students and researchers engaged in the fascinating realm of natural products. These services include but are not limited to the following:

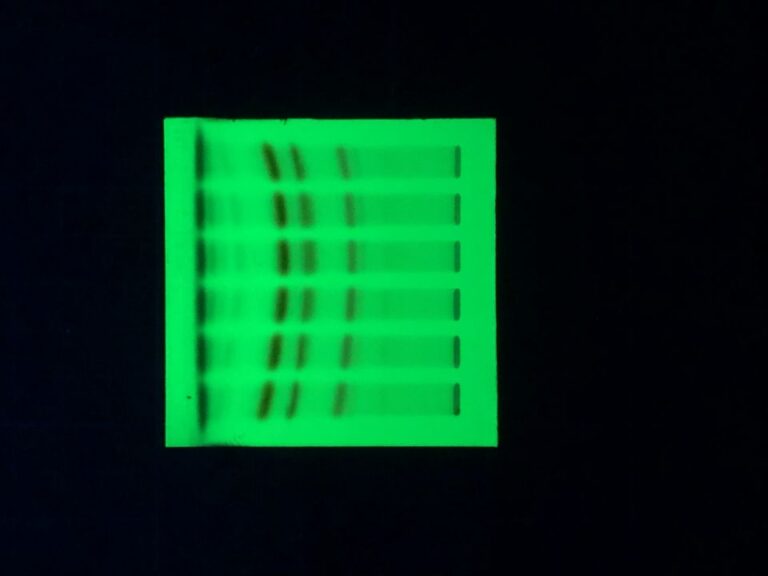

- Phytochemical Profiling (TLC/HPTLC)

- Phytochemical Quantification (HPTLC)

- Biochemical Assays (Polyphenols, Flavonoids, Antioxidants)

Enzyme Inhibition Assays (Amylase, Glucosidase) - Antimicrobial Screening Assays

Microbiological QC Analysis (Food, Drug, and Cosmetics) - Physicochemical Analysis (e.g., pH, TDS, conductivity, °Brix, alcohol content, moisture content, water activity, titratable acidity, etc.)

- Total Organic Carbon Analysis (Pharmaceutical Water)

- Contaminants Analysis (Total Aflatoxin, Aflatoxin B1)

- Custom Method Development and Validation

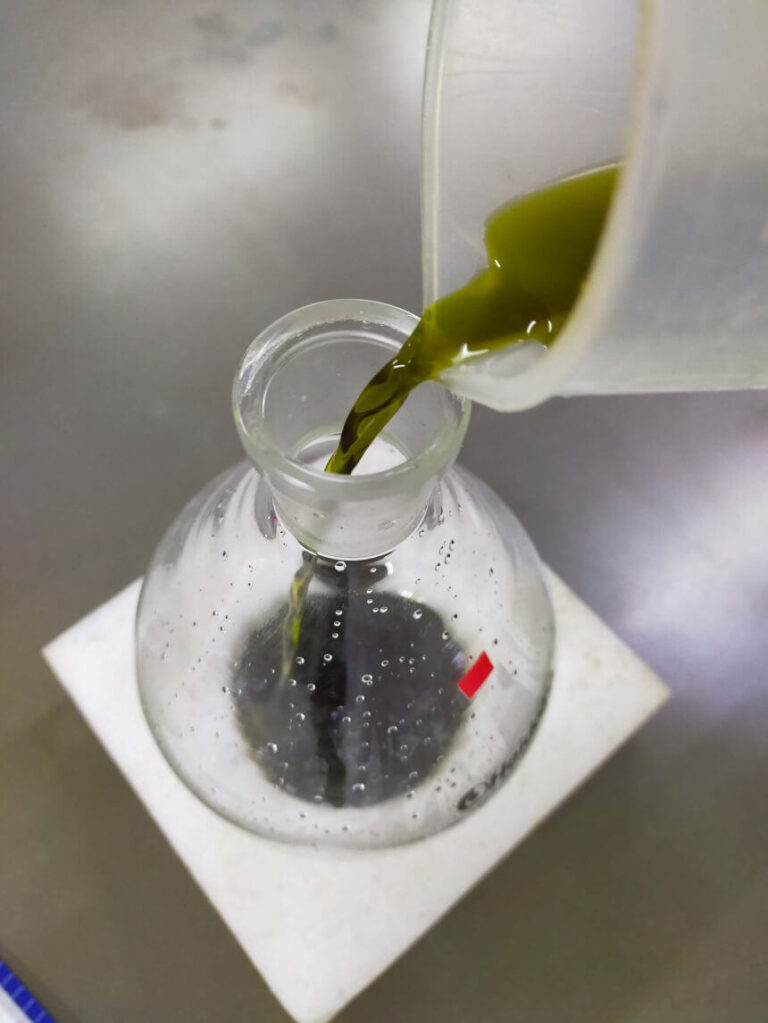

Pilot Scale-Up Laboratory

Based in the Applied Research & Innovation Laboratory (ARIL), our Research & Development unit specializes in the use of various raw material processing, extraction, purification, and compounding techniques at the lab and pilot scale to develop high quality and potent botanical ingredients and finished products.

We work through a fee-for-service model to extend our pilot extraction facility to support the scale-up of academic research in natural products. These services include the following:

- Hydroalcoholic Extraction

- Subcritical Solvent Extraction

- Oil Press Extraction

Steam Distillation - Vacuum Concentration

- Liquid-liquid Partitioning

- Spray Drying

- Drum Drying

Forced Air Oven Drying - Microfiltration

Puff Extrusion - Wet Granulation

Capsulizing - Tableting

Inquire Now!